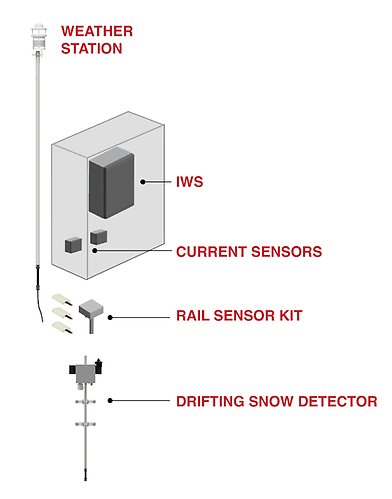

Intelligent Weather Station (IWS)

The Intelligent Weather Station (IWS) is an advanced control and monitoring system, developed in conjunction with NIBE’s electric track switch heating systems, that automates existing rail heating currently in place—legacy systems—for optimal performance and energy efficiency.

The IWS monitors conditions continuously, including:

- Air temperature

- Rail (track) temperature

- Humidity

- Wind speed and direction

- Precipitation (snow, rain, freezing rain)

Using real-time data, along with predictive algorithms to assess the risk of ice or snow accumulation on rails or switches, the IWS automatically activates or deactivates existing rail heating elements through an attachment to the legacy controller. Over time, machine learning and algorithms adapt to historical data, further refining activation thresholds and optimizing performance.

The IWS uses the same automated intelligent SCADA algorithms, call the Blue Engine, as the following:

As part of an integrated automated electric rail heating system, the IWS enables significant energy savings. At several U.S. rail authorities where NIBE heating systems have been implemented, energy savings as high as 80% and higher have been achieved.

Automating an Existing Legacy System

If you have an existing legacy system, the IWS is a cost-effective way to automate rail switch heating without replacing your entire infrastructure. An IWS-enabled system provides the same operational efficiency as the BLUE POINT system, while saving 60% or better in energy costs.

A conventional rail heating system typically runs 100% of the time during the winter months in manual mode and many hours beyond or before needed in dispatch mode.

Automating your legacy system using NIBE’s IWS enables you to apply heat in response to changing weather conditions, rather than running heat continuously or inefficiently.

NIBE IWS enables:

Automating a legacy heating system involves retrofitting old, manually controlled or semi-automated systems with modern sensors, controls, and remote monitoring. NIBE’s IWS runs on a BLUE POINT platform and is attached to your system’s legacy controller which is driven through dispatch. Externally, temperature sensors are placed on the tracks.

The IWS works identically to the BLUE POINT heating platforms, except for the positioning of the two control systems. Instead of being tightly coupled within one enclosure, the two control systems—the existing legacy controller (high power) and IWS (low power)—are separated. The low power section of the platform is replaced with a standalone IWS that is attached to, or placed close to, the existing legacy controller. The IWS uses the same weather station and rail sensors as the BLUE POINT platform to drive the controller.

The IWS automates your existing legacy controller, providing real-time data and monitoring for hassle-free “Operator Out of the Loop” operation and maintenance. On-demand heat optimizes performance and reduces equipment wear and tear, while delivering up to 60% plus in energy savings.

By augmenting your existing infrastructure with the IWS, you can realize the benefits of NIBE’s advanced automated rail heating technology—at a fraction of the cost of replacing a controller or installing an entire new system.